Heat Recovery from Air compressor

Product Details:

- Type Industrial

- Click to View more

Heat Recovery from Air compressor Price And Quantity

- 1 Number

Heat Recovery from Air compressor Product Specifications

- Industrial

Heat Recovery from Air compressor Trade Information

- 10 Number Per Year

- 15-20 Days

Product Description

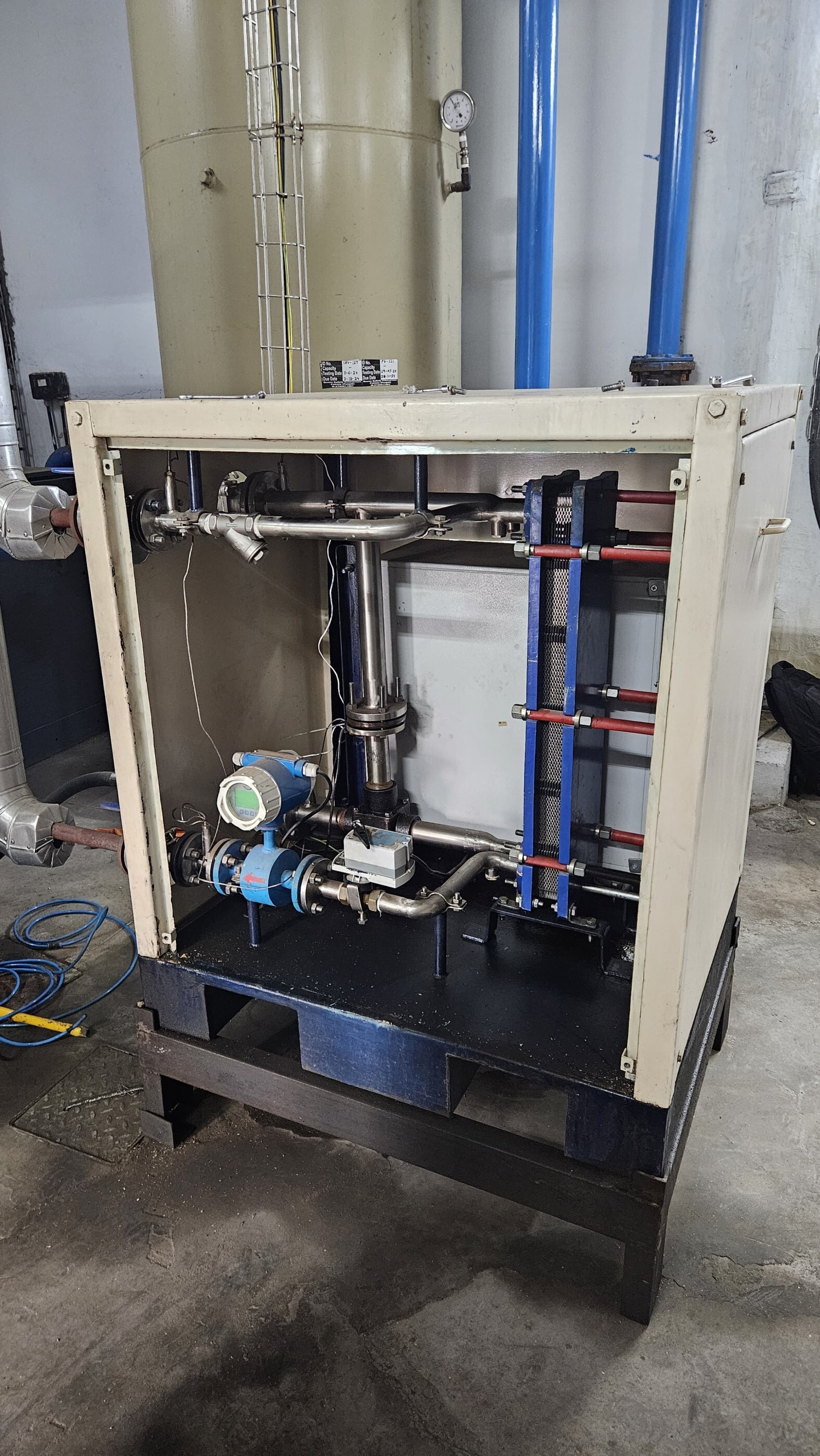

Heat recovery from air compressors is a strategy to maximize energy efficiency by utilizing the thermal energy produced during compressor operation. Air compressors generate a significant amount of heat as a byproduct of compressing air, which is often expelled into the environment as waste. Heat recovery systems capture this excess thermal energy and redirect it for use in other applications, such as heating water, space, or industrial processes.

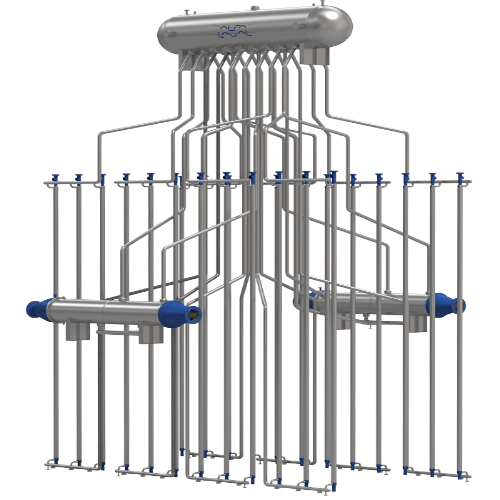

The process typically involves installing a heat exchanger that transfers the heat from the compressorïs cooling system to a secondary medium. This recovered heat can be used for purposes like pre-heating water for industrial processes, heating building spaces, or even generating additional power in combined heat and power (CHP) systems. By recovering and reusing this waste heat, companies can reduce their energy consumption, lower utility bills, and enhance their overall operational efficiency. Additionally, it supports sustainability goals by decreasing the carbon footprint and minimizing waste heat emissions.

FAQs on Heat Recovery from Air Compressors

1. What is heat recovery from air compressors?

Heat recovery from air compressors involves capturing the waste heat generated during the compression process and repurposing it for other uses, such as heating water, space heating, or industrial processes.

2. How does heat recovery from air compressors work?

Air compressors generate heat as they compress air. This heat can be captured using a heat recovery system, such as a heat exchanger or a cooling system that transfers the heat to another medium, like water. The recovered heat can then be used to preheat water, heat spaces, or support other thermal processes.

3. What are the benefits of heat recovery from air compressors?

- Energy Savings: Utilizes waste heat, reducing the need for additional energy sources.

- Cost Reduction: Lowers operational costs by repurposing heat instead of generating new heat.

- Improved Efficiency: Enhances the overall efficiency of the air compression system.

- Environmental Impact: Reduces greenhouse gas emissions by making better use of generated energy.

4. What types of heat recovery systems are used with air compressors?

- Heat Exchangers: Transfer heat from the compressed air to water or other fluids.

- Water-to-Air Heat Exchangers: Capture heat from the compressor and transfer it to air for space heating or ventilation.

- Integrated Heat Recovery Systems: Systems designed to capture and reuse heat from both the compressor and its cooling system.

5. What industries benefit from heat recovery from air compressors?

Industries such as:

- Manufacturing: Use recovered heat for process heating or facility heating.

- Food and Beverage: Repurpose heat for heating water or space within processing plants.

- Chemical Processing: Utilize heat for various thermal processes or preheating feedstocks.

- Pharmaceuticals: Apply recovered heat to support energy-intensive processes.

6. What factors should be considered when designing a heat recovery system for air compressors?

- Heat Output: Determine the amount of heat generated by the compressor and its suitability for recovery.

- System Integration: Ensure compatibility with existing equipment and processes.

- Heat Demand: Identify where recovered heat can be effectively used within the facility.

- Maintenance Requirements: Design the system to be easily maintainable and reliable.

7. How much energy can be recovered from an air compressor?

The amount of recoverable energy depends on the compressor's size, efficiency, and operating conditions. Typically, a significant portion of the waste heat can be captured and utilized, leading to notable energy and cost savings.

8. How does heat recovery from air compressors contribute to sustainability?

By capturing and reusing waste heat, heat recovery systems reduce the need for additional energy sources, lower energy consumption, and decrease greenhouse gas emissions, contributing to more sustainable industrial practices.

9. What maintenance is required for a heat recovery system from air compressors?

- Regular Inspection: Check for fouling, leakage, and wear in the heat recovery system.

- Cleaning: Clean heat exchangers and related components to ensure efficient heat transfer.

- System Monitoring: Continuously monitor the performance to ensure optimal heat recovery and system operation.

10. Can heat recovery systems be retrofitted to existing air compressors?

Yes, heat recovery systems can often be added to existing air compressors with appropriate modifications, enhancing energy efficiency and reducing operational costs without significant changes to existing infrastructure.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free